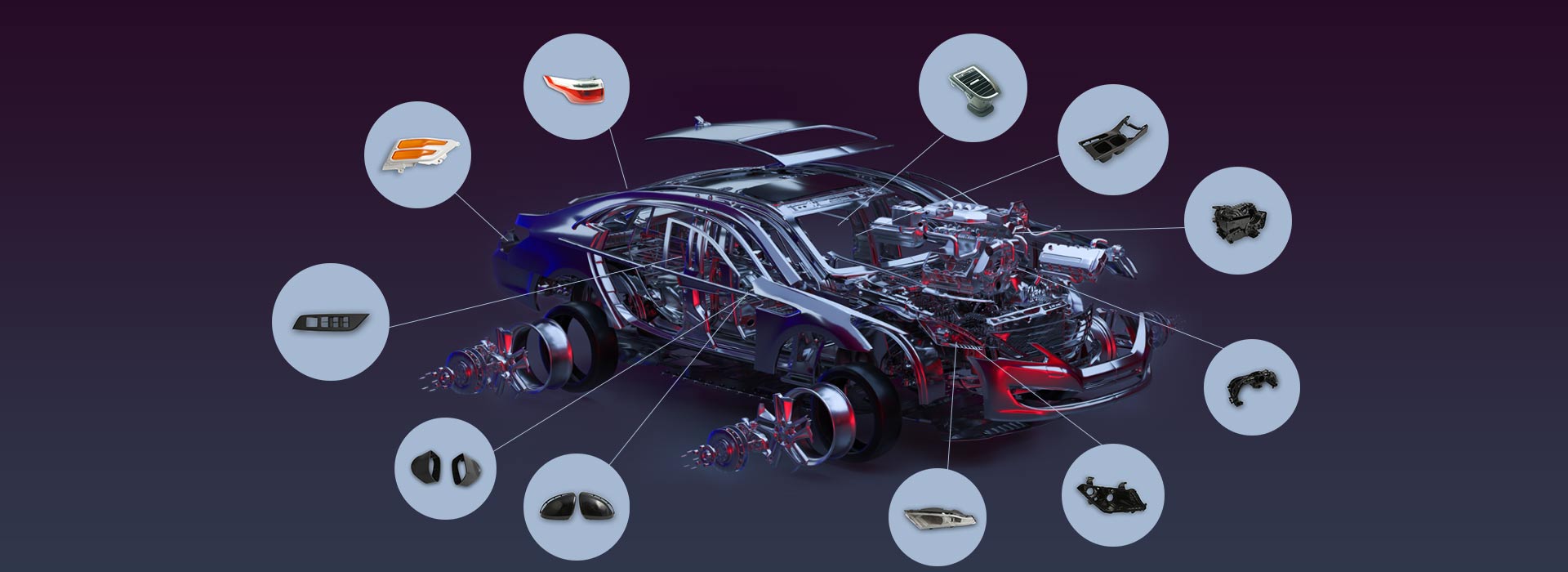

Injection Molding in the Automotive Industry

Injection molding stands as a cornerstone in modern manufacturing, especially in the automotive sector. Its overarching advantages redefine how complex-shaped parts with strict tolerances and exceptional surface finish are produced.

Precision in Complexity

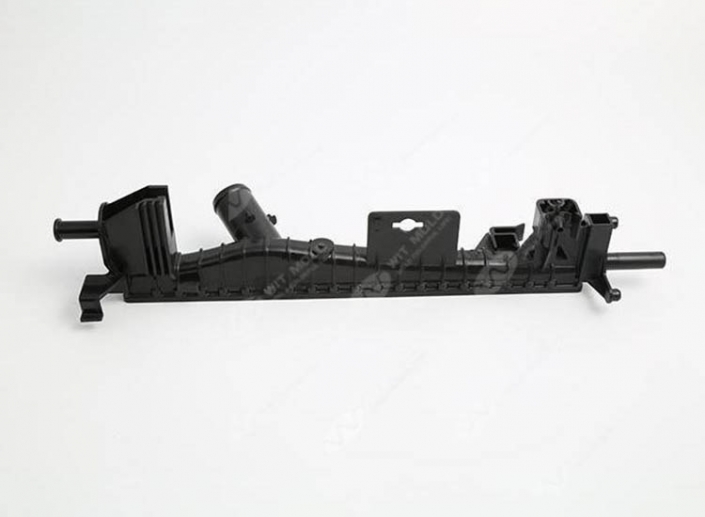

Injection molding excels in crafting intricate components with stringent tolerances, setting a new standard for precision and complexity in the automotive industry.

Versatility and Scalability

The multifaceted nature of injection molding makes it a versatile solution for various automotive parts. Its scalable process allows for the mass production of thousands of identical components.

Types of Injection Molding in the Automotive Industry:

1. Thermoplastic Plastic Injection Molding:

Widely Employed in Automotive Manufacturing

Thermoplastic injection molding, using materials like polypropylene, nylon, and ABS, is the go-to method in the automotive industry.

Key Highlights:

Cost-Effectiveness: Offers a cost-efficient solution for producing automotive components.

Speedy Production: Boasts fast production rates, meeting the demands of the automotive sector.

Multifunctionality: Versatile in applications, addressing a range of automotive part requirements.

2. Elastic Injection Molding:

Enhancing Automotive Performance

Designed for producing parts from elastic materials like rubber and silicone, elastic injection molding shares similarities with thermoplastic molding but introduces exceptional shock absorption and vibration reduction.

Notable Features:

Shock Absorption: Elevates the durability of automotive components through effective shock absorption.

Vibration Reduction: Ensures a smoother ride and prolonged lifespan with superior vibration reduction.

Cost-Effective Durability: Combines longevity with cost-effectiveness, a crucial aspect for automotive manufacturing.

3. Thermoset Injection Molding:

Enduring Strength in High Temperatures

Utilizing materials such as epoxy resin and polyester, thermoset injection molding highlights precise dimensions, repeatability, and resistance to high temperatures.

Key Advantages:

Dimensional Precision: Ensures automotive parts meet stringent size tolerances consistently.

High-Temperature Resilience: Resists melting or deformation at high temperatures, a key consideration for automotive manufacturers.

Repeatability: Guarantees the production of identical components with every manufacturing cycle.

Advantages of Injection Molding in the Automotive Industry:

The widespread use of injection molding in the automotive industry stems from its superiority over traditional manufacturing techniques.

Key Advantages:

Accuracy and Reproducibility: High precision and reproducibility are paramount in automotive manufacturing, a core reason for the industry’s preference for injection molding.

Complex Shape Design: Injection molding enables the production of intricate components with a process called “screw-injection,” facilitating the creation of detailed and complex parts.

Rapid and Efficient Manufacturing: The swift production process ensures that automotive manufacturers can meet their part demands efficiently.

High Surface Finish Quality: Components produced through injection molding boast excellent surface finish quality, offering smooth and flawless surfaces.

Color Variety: Injection molding allows for the production of parts in various textures and colors, eliminating the need for post-molding coloring processes.

In summary, injection molding in the automotive industry embodies precision, versatility, and efficiency, revolutionizing the way complex automotive components are designed and manufactured.